Know the Solutions for the Most Common Gerber Files Problems

Have you experienced issues with Gerber files in your PCB Assembly? This is a common challenge many face when analyzing board layout and design as well as manufacturing.

Have you experienced issues with Gerber files in your PCB Assembly? This is a common challenge many face when analyzing board layout and design as well as manufacturing.

A stackup is an arrangement of PCB layers of conductors and dielectric materials, which enables the incorporation of multiple boards compactly within a device. This mostly includes the substrate, such as polyimide by upper and lower layers of copper, followed by adhesive and cover layers on both sides.

Multilayer Printed Circuit Boards (PCBs) are used in today’s sophisticated electronic devices. Known for their increased functionality, higher circuit density, and superior performance, these boards are the go-to choice for advanced technological applications. However, due to their intricate design, the assembly costs for multilayer PCBs can be significantly higher than their simpler counterparts. Understanding the main cost drivers is critical for managing expenses effectively. This post explores the key factors that majorly impact the pricing of multilayer PCB assembly.

Printed circuit board (PCB) design is a systematic process involving components, layouts, connections, and more that are appropriately arranged together to assemble.

When it comes to high-frequency PCB design, the choice of material is critical to ensuring optimal performance and signal integrity. One of the critical materials used in PCB design is FR4.

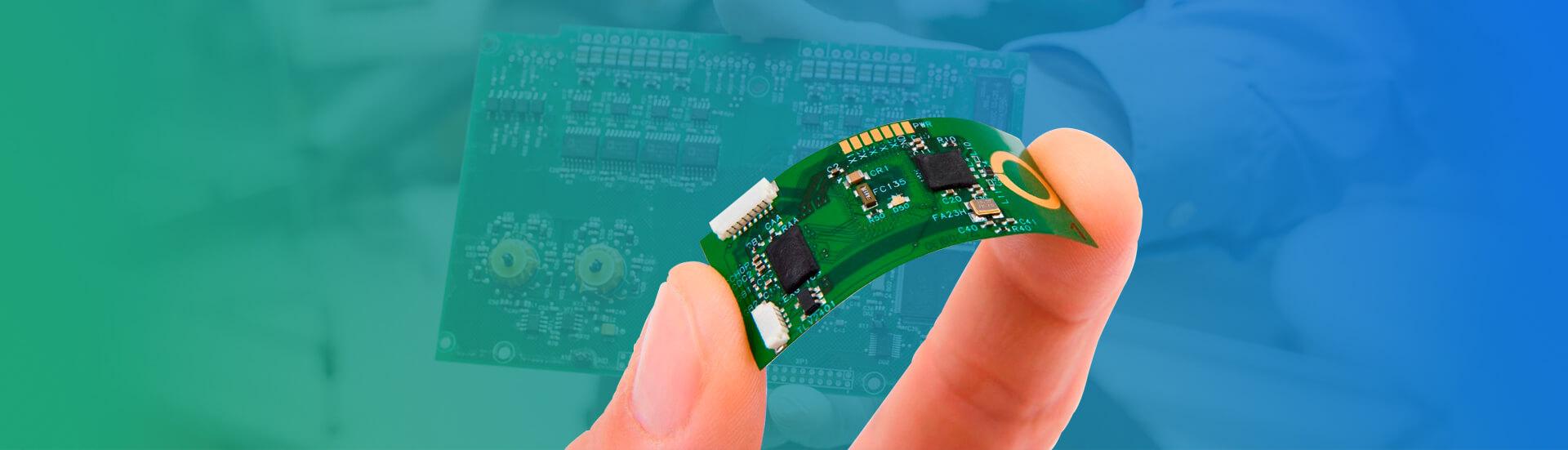

Flexible printed circuit boards or flex PCBs are indispensable in electronics applications due to their flexibility, lightweight designs, and adaptability. Despite their utility, flex-printed circuit boards have certain limitations. One such limitation is the lack of rigidity in areas where it is necessary.

A via or vertical interconnect access is a hole in a printed circuit board that is drilled through the board layers and is also comprised of conductive materials like copper filled within to facilitate electrical connection between various PCB layers.

The reliability and performance of every PCB component are crucial to the functionality of electronic devices. Among these, electrical connectors are essential as they form the critical interfaces between various electronic components. The quality of these connections directly impacts individual devices and the overall system.

When it comes to printed circuit boards (PCBs), effective temperature management is crucial to ensure their optimal performance and longevity. From significantly reducing heat-induced component failures to optimizing signal integrity, understanding and controlling PCB temperatures is essential.

In the printed circuit board assembly, most assemblers have to choose between lead and lead-free solder. With the stringent regulations and growing environmental concerns, there has been a massive shift towards lead-free solder alternatives in recent years.

As we all know, wearable technology has become integral to our daily routines. From fitness trackers and smartwatches to medical devices, we depend on this technology, right? In every wearable device, there is a crucial component that supports and connects the electronic elements of the device, and that is the printed circuit board (PCB).

Moisture sensitivity in PCBs are a significant concern that can adversely impact the quality, reliability, and performance of electronic devices. When moisture penetrates a PCB, it can lead to several problems such as corrosion, delamination, and the formation of conductive pathways, which can cause short circuits.